About MLG Instruments

MLG Instruments Schiedam has many years of experience in designing and producing magnetic level gauges for various applications. All our products are manufactured according to the (often widely diverging) wishes and requirements of our customers.

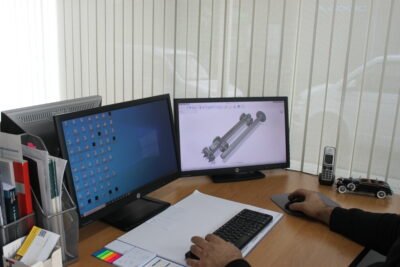

Our team

We have an enthusiastic and motivated team who enjoy getting their teeth into a challenge – and they’re ready to make the impossible possible for our customers. This is because we are passionate about what we do and we want to continue developing our skills.

In our organisation, we’re always aiming to make the good even better. When legislation and regulations change or when an internal process is modified, we make sure there is in-house training or education.

Magnetic level sensors made by MLG Instruments Schiedam are zero-maintenance and suitable for indirect visual observation of the level in a closed tank, allowing you to control your system either mechanically or electronically.

Service and an innovative, result-oriented approach underpin our work for all of our customers, allowing us to provide the best possible service.

The benefits of choosing MLG Instruments Schiedam as your partner:

What it means for our customers:

- Short lines of communication about the technical options

- Short delivery times (for both mechanical and electronic items)

- Quick service (because everything is managed entirely in-house)

- Standard accessories such as stop valves, gate valves, piston valves, ball taps, 3-way valves, filters, regulators, spring-loaded safety valves, orifice plates or other technical components. These products are bought at competitive prices through our contacts abroad (worldwide via distributors representing us).

MLG Instruments Schiedam product range (produced in-house at the Schiedam site)

- Magnetic level gauges

- Transmitters, 4 – 20mA (Hart7, Profibus, Fieldbus)

- Switches

- Float switches

- Radar chambers (to be combined with guided wave radar measurements)

MLG Instruments Schiedam has the following certificates and our products are supplied in accordance with various norms:

Management System

- ISO 9001-2015 Certificate number: 00032510

PED – Pressure Equipment Directive

- Type approval Bureau Veritas (PED) Cat.III/IV NoBo nummer CE 1117

- European Pressure Equipment Directive 2014/68/EU

- Design code DIN according to EN-13455

- Design code ANSI according to ASME VIII div. 1

ATEX – ATmosphères EXplosibles

- ATEX EU – Type approval certificate number: KIWA 17ATEX0029

- ATEX Directive 2014/34/EU II 1G Ex h IIC or IIB+H2 or IIB or IIA T1…T6 Ga

- ATEX Directive 2014/34/EU II 1D Ex h IIIC T450°C…T85°C Da

IECEx – International Electrotechnical Commission for Explosive Atmospheres)

- IECEx Type approval certificate number: KIWA 18.0005

- IECEx Ex h IIC or IIB+H2 or IIB or IIA T1…T6 Ga

- IECEx Ex h IIIC T450°C…T85°C Da

DNV

Type approval Marine

- Certifcate number: TAP000026H