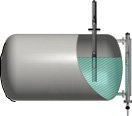

A magnetic level gauge (also called magnetic level indicator) is attached to the side or top of a tank containing a liquid using flanges or a threated connection. The device consists of a bypass chamber with an indicator rail on the outside with flappers attached. There are small magnets in those flappers, which are red on one side and white on the other.

The bypass chamber (measurement tube) and indicator are both made of non-magnetic material. The bypass chamber contains a float with a cylindrical magnet.

Magnetic level gauges work by the principle of communicating vessels: the level in the bypass chamber is therefore equal to the level in the tank. The custom-made float is drifting on the liquid in the bypass chamber and the magnet inside repels the small magnets in the Flappers. As the magnet in the float inside the bypass chamber moves up and down, its magnetic field makes the flappers rotate, thereby showing the level of the liquid.

The flappers that are depicting red indicate how much liquid is in the tank, the white ones show the proportion of the tank that is empty, containing only gas.

Magnetic level gauges are also suitable for indicating the interface between two different liquid phases in a vessel or tank.

On top of that, they are zero-maintenance and unaffected by dust, impacts, vibrations, moisture or high temperatures. They can even be used in environments where corrosive or acidic substances are used.

If desired, measurement devices with electronic components such as switches and transmitters can also be supplied.